From Bill Watterson, the creator of one of the most memorable and treasured things from my childhood; Calvin and Hobbes, comes some truly grounding words of wisdom.

Enjoy!

Greetings all!

I am working on developing my thesis project now, and it is becoming very exciting. My topic is parkour!

After much evolution and boiling down, my current direction is to come up with a way to make parkour in its purest sense to be more accessible to newcomers while offering new opportunities for challenge and interaction with participants.

At present I’m thinking of a kind of geocache locator beacon that traceurs can place as they go for a run. Also a purpose-designed backpack that runners can carry the beacons (and other gear) in without restricting movement or getting in the way.

Please post comments for feedback or advice along the way!

Oh, and if you have a moment, please take this very brief survey for my research (I’ll try and keep them bite-sized.

https://www.surveymonkey.com/r/JTCDDXN

Thanks!

Assembling the crossbow piece by piece. Upped the ante by building the riser out of purpleheart with a layer of 16 gauge steel for reinforcement. Also routed slots in the sides so the limb pockets will be flush for the final.

Tried my hand at cutting fiberglass stock (despite warnings from the shopkeep) with unexpectedly positive results! Probably the smoothest part of the build so far…

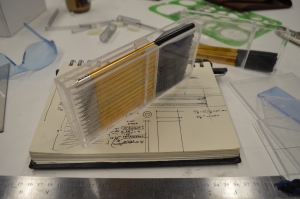

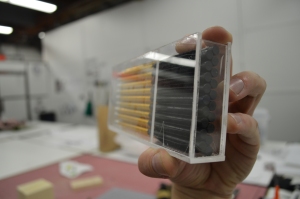

So the first one was a good proof of concept, but it would have taken far too long to precisely sculpt out the magazine pockets, and I thought making it a bit more stylish and robust would not be amiss.

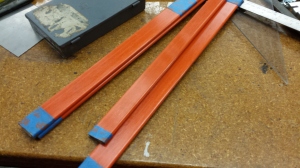

So I laminated poplar with layers of 3/16″ red acrylic. First and foremost to provide the perfect spacing for the 7/8″ wide magazine, but also to give the opportunity (when time allows) to add lighting elements and make the acrylic glow from the inside a la Tron.

I used this opportunity to make the pockets from the get go, separating the blocks comprising the middle layers by the length of the magazines. This will save both materials and a great deal of time when it comes to the final assembly. Tricky to get things clamped properly, but well worth it.

Hello all!

I do apologize for my absence as of late. Never fear though, it was the result of my working on the prototype(s) pretty much nonstop. I now have 24/7 access to a local workshop and have been making the most of it.

The following shows the rail/carriage mechanism on my first prototype (Pictures of round two to come once they finish uploading).

Several unfortunate events occurred today, but were surpassed by great advances. The trigger broke (not surprising) so I made a new one of metal. Tomorrow I’ll add some red plexiglass between the plates.

Then part of the riser broke (again not surprising) but now I can streamline the design further.

The stock cams I was planning to use don’t offer a long enough power stroke, so I had to rework that too.

Finally I used the tube bender for the first time and the rails came out perfectly! (Excuse the phone photo, didn’t want to take my D3200 into the metal shop)

Tomorrow I have work, but should be able to make a little crossbow movement.

Hello all!

I am now working for a small start-up designing and manufacturing RFID units for race organizers. Although this cuts into my crossbow time, it also feeds me…and gains me full access to one of San Francisco’s best-stocked maker shops!

To sweeten the pot…the shop will be open 24/7 starting next Friday so be prepared for some serious progress…and eye-baggage.

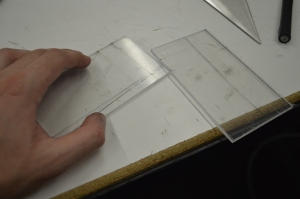

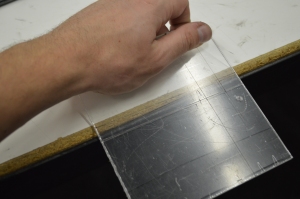

I had a minor epiphany regarding how the magazine could work and promptly made a couple proportional mock ups out of acrylic. I’ll prototype the mechanism soon, but I’m going between the ideas of an in-line mag and staggering the bolts. The latter would offer roughly twice the capacity, but brings with it some complications.